$89 Flat Repair Fee

With the new Ohio Medical Diamond Repair Service program, we make it easy for you to get your Ohio Medical or Amvex Suction Regulators serviced or repaired.

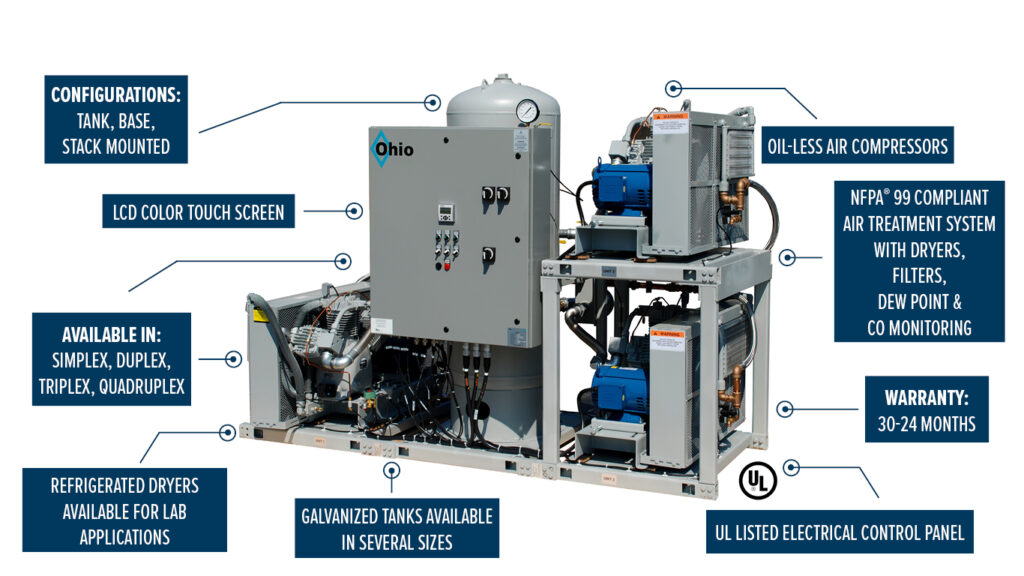

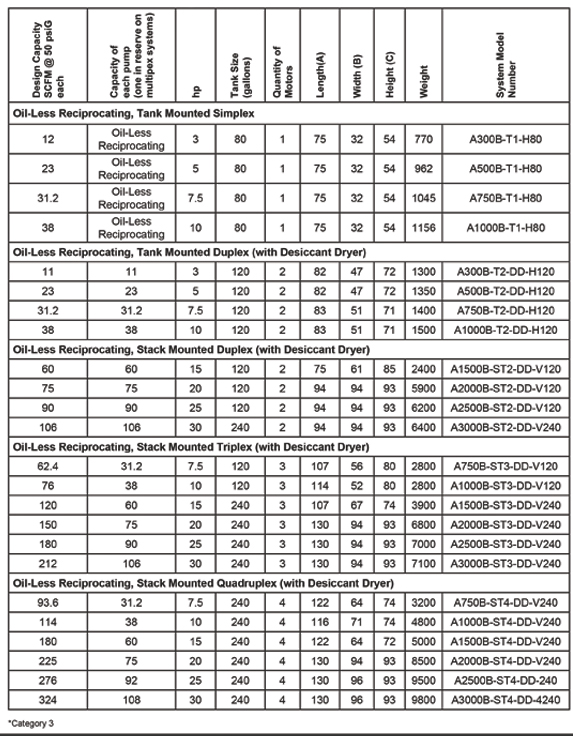

Ohio Medical reciprocating NFPA 99 compliant air compressor systems consist of electric motor driven Oil-Less air compressor(s), an Underwriters Laboratories listed electrical control mounted in a NEMA 12 enclosure, ASME air receiver, air cooled aftercooler(s) with individual drain(s), inline intake air filter(s) and an air treatment module. The components are modularly assembled to accommodate most existing doorways. The system includes interconnecting copper/brass piping and wiring to provide a functional operating package with applicable electrical and plumbing connections at the installation site. The packaged unit is factory tested prior to shipment and warranted for a period of 30 months from date of shipment or 24 months from date of start-up.

The compressor(s) consists of a crankcase, connecting rods, integral counterweights for smooth operation, and cylinders and heads designed for efficient heat dissipation. Piston rings are provided to reduce wear and have a life span of 10,000 hours. Each compressor cylinder is protected by a temperature switch, which will stop the drive motor and provide an alarm signal in the event of abnormal discharge air temperature. Each belt driven compressor module includes an inline filter with a particle retention of 5 microns, inlet isolation valve discharge isolation valve, and ASME safety pressure relief valve.

The corrosion resistant coated receiver is equipped with an ASME safety pressure relief valve, sight glass pressure gauge, automatic drain, three-valve by-pass and source isolation valve.

The corrosion resistant coated receiver is equipped with an ASME safety pressure relief valve, sight glass pressure gauge, automatic drain, three-valve by-pass and source isolation valve.

The air treatment module includes dual dryers, dual filtration system, a CO and Dew Point monitoring device with local audible and visual signals and dry contacts for remote monitoring. The components are mounted on a common base with interconnecting copper/brass piping and upstream and downstream isolation valves. The isolation valves allow either set of components to be serviced without shutting down the system.

The dryer system is duplexed and provides a pressure dew point of 10°F. Dryers are heatless desiccant design selected and sized to provide for the peak-calculated demand. The desiccant dryer is equipped with a dew point Dependent Switching feature to minimize the need to purge air.

The dual filtration system is designed to remove liquids and particulate matter, it also consists of one micron coalescing filters with differential pressure indicators, automatic drain, air line pressure regulators with gauges, final pressure relief valve and sampling valve.

The UL listed electrical motor control system contains a fuseless design in a NEMA 12 enclosure. The “Continuous On Demand” feature stops the operation of the motor(s) during periods of low or no demand. The controls include individual self protected combination motor control(s) with short circuit, single phase and thermal overload protection, individual 120 volt control circuit transformer(s) with fuseless primary and secondary protection, pressure sensors, temperature switches with reset button, and an electronic controller to automatically change the operating sequence of the compressor(s). The cabinet door has an HMI (Human Machine Interface) Color Touch Screen system status display to include system pressure, dewpoint, pump operation, accumulated time, maintenance interval, fault conditions, and silence button; lighted Hand-Off-Automatic selector switch(es) and safety disconnect operating handles.

All required local alarm functions are integrated into the packaged system. The circuitry is designed so the visual indicator will remain until the fault has been cleared and the reset button actuated. Local alarm functions are provided for high air discharge temperature and thermal overload.

All required local alarm functions are integrated into the packaged system. The circuitry is designed so the audible signal can be silenced and the visual indicator will remain until the fault has been cleared and the reset button actuated. Local alarm functions are provided for reserve pump in use (lag alarm). Dry contacts and/or remote communication protocols provided for remote alarm signals or BMS.

Included for job site installation are inlet and discharge flexible connectors, vibration mounting pads, source isolation valve, and touch-up paint.

With the new Ohio Medical Diamond Repair Service program, we make it easy for you to get your Ohio Medical or Amvex Suction Regulators serviced or repaired.

Routine preventative maintenance (PM) is required to help reduce costly failures, leaks and unnecessary downtime. An Ohio Medical System Maintenance arrangement is an excellent and cost effective way to make sure that routine preventative maintenance is performed on all of your Medical Gas equipment.